RVP - Retro Fit Valve Pack

The importance of good compressed air supply.

Air impact markers require a larger and more instantaneous air flow compared to standard air cylinders because they need to deliver a high force in a very short period. This rapid burst of air creates the impact necessary for marking applications, especially in industrial environments where precision and speed are critical. Unlike typical air cylinders, which operate more gradually and can sustain a consistent flow over time, air impact markers must compress and release air quickly to achieve the desired marking force, making fficient air flow management crucial for their performance.

Two Most Common mistakes when preparing an air circuit for an air impact marker:

- Air Starvation

- Cycle time too long

Is an Air Impact Marker the Same as an Air Cylinder?

No. Despite both using compressed air, they operate on different principles:

- Air Cylinder: Generates linear motion through air pressure and piston area, calculated by the equation F = P x A. For example, the Model 298 cylinder produces 165 lbs of force at 80 psi.

- Air Impact Marker: Operates on the principle of F = MA (Force = Mass x Acceleration). The acceleration of the rod/stamp holder generates high force output, resulting in 16,000 lbs of impact force with the same 80 psi.

Product Information

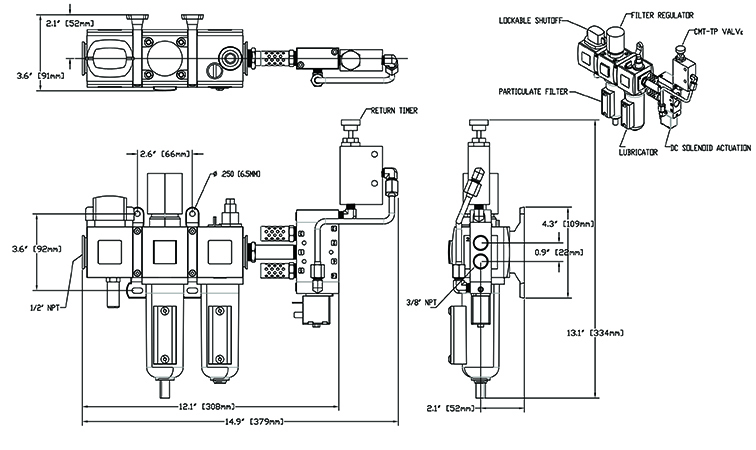

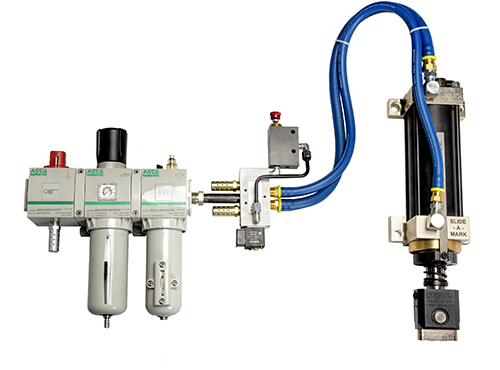

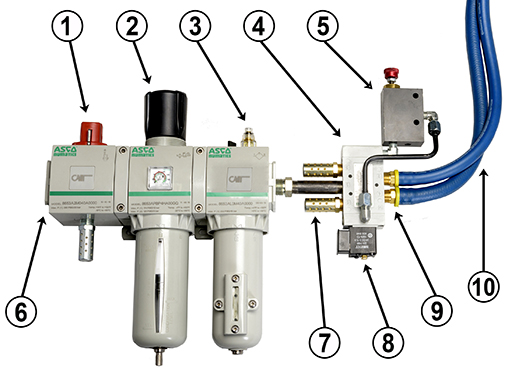

The easy-to-use valve pack from Columbia Marking Tools for the air impact markers includes

- Filter- Regulator to both clean the air supply and control the air pressure used during the air impact marker application

- Lock out – safety lock out as required by OSHA for standard safety protocols during maintenance and repair.

- Lubricator – for the lubricated air supply.

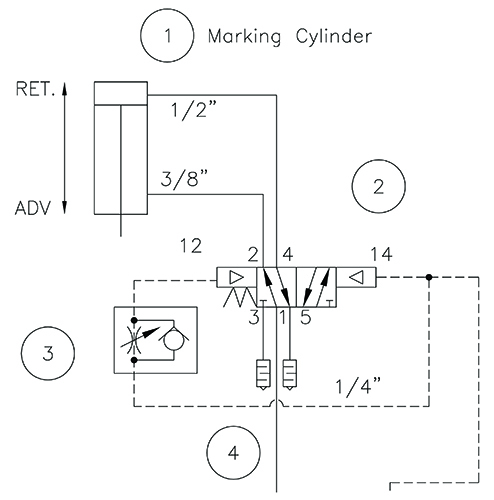

- Valve – either 3-way for the single acting air impact markers, or 4-way for the double acting air impact markers..

- Assembled and ready to mount

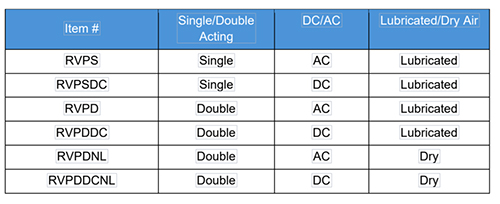

Select the valve pack required from the item chart. The three options include:

- Single or double acting. The model 88 and 98 are the only single acting units

- Solenoid controls are available for DC or AC.

- Filter/Lubricator is dependent on the type of shop air provided. Either Dry air or lubricated air.

- Safety Lockout – OSHA required

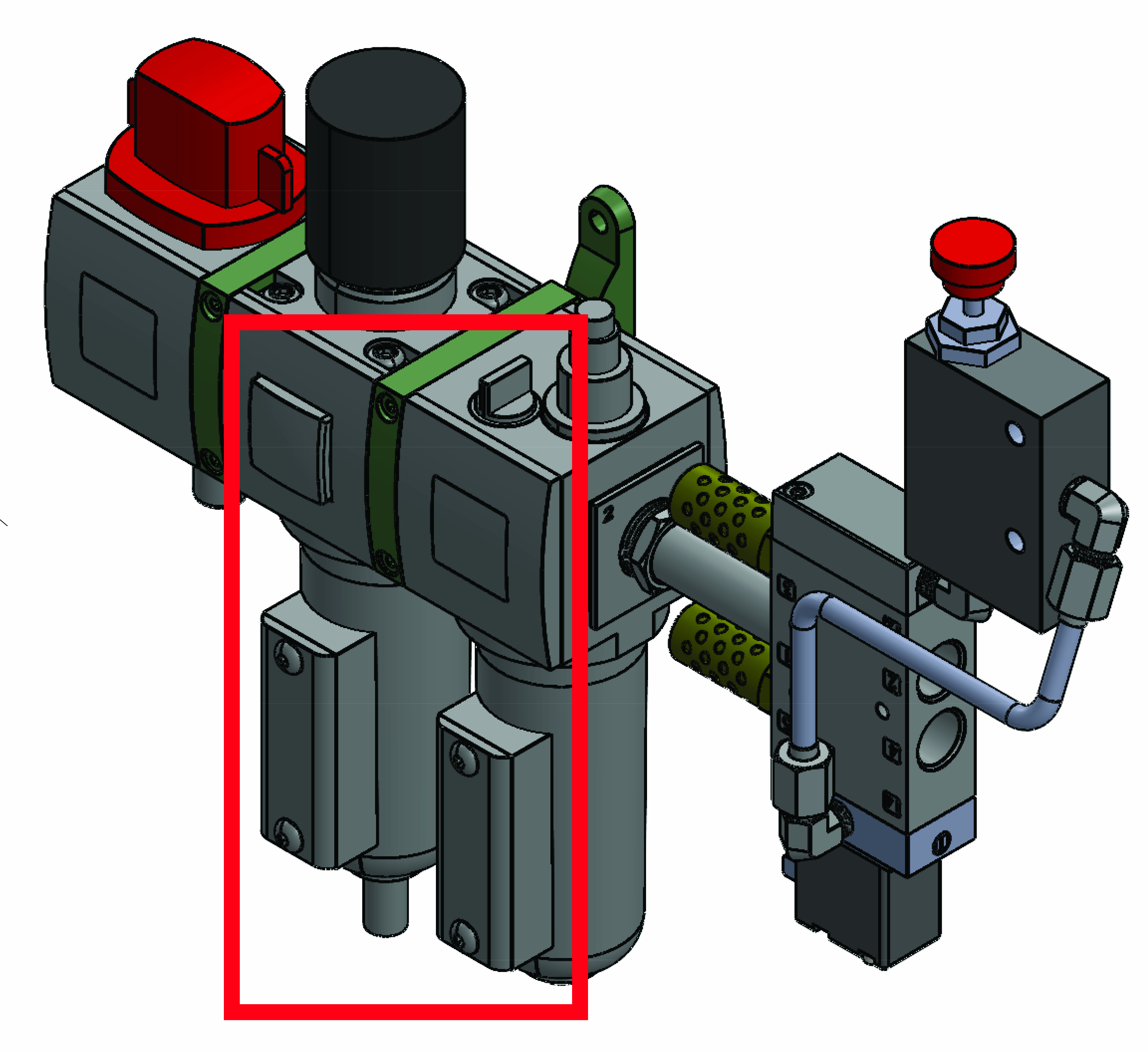

- Filter/Regular

- Lubricator, regular or coalescent for dry air supply

- Valve, 3-way or 4-way

- Timer

- 1/2” NPT connection for Shop Air

- Muffler (2)

- DC or AC solenoid for valve

- Fitting for 3/8” NPT valve connection (1 or 2) - sold separately

- Hose (1 or 2) to connect to impact marker - sold separately

Technical Details

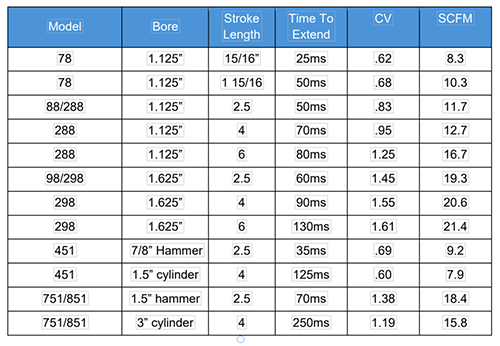

A simple chart gives various information for Air Impact Models. The information includes the bore size, stroke length, and relative time to extend, CV, SCFM, and expected drop in pressure of the compressed air.

The Air Impact Marker is not generated solely dependent on the air flow. The force is a combination of the air pressure and speed at which the rod/hammer is moving.

Columbia Marking Tools uses a standard valve with 1.7 cv for all our air impact markers.

IMPORTANT NOTE

The drop in air pressure must not exceed 2 psi for any installation or the air impact marker will not provide the optimal designed force.

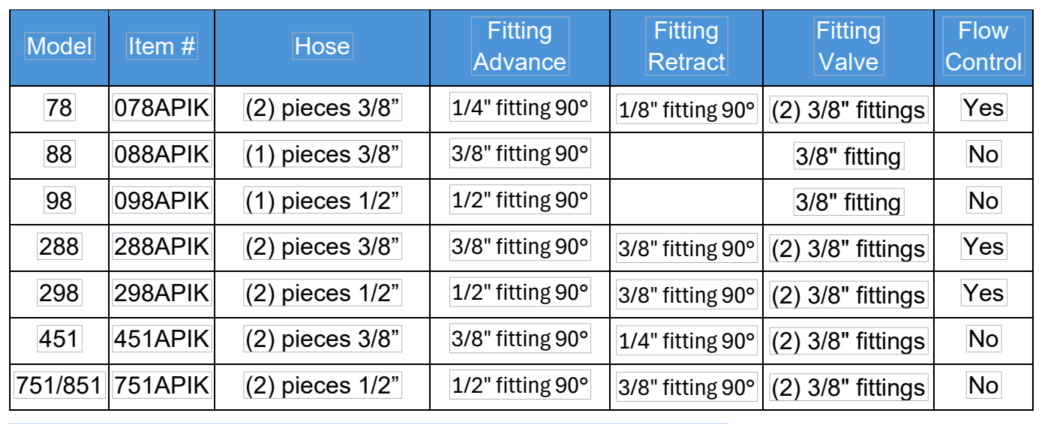

The CMT air impact marker fittings kit contains the recommended components to connect the CMT impact marker to the RVP valve pack.

Items Included:

Designed for use with lubricated air supply systems, these replacement parts are provided with standard components included. Optional upgrades are available for purchase as spare parts to enhance performance. Maintenance schedules will vary based on the quality of the local air supply, ensuring optimal operation and longevity.