CMT Roll Marking Machines

Roll Marking: A Cost-Effective Solution for Precision Marking

Roll marking is a highly efficient and economical marking method that "rolls" the imprint onto a part, reducing the need for high tonnage presses. This technique is particularly beneficial for applications where excessive force would be costly or could damage delicate components. By applying characters one at a time, roll marking minimizes required force, extends equipment longevity, and lowers overall machinery costs.

This method is versatile, accommodating both round parts with flat dies and flat parts with round dies, making it suitable for a variety of shapes and surfaces. Columbia Marking Tools (CMT) offers a wide range of roll marking solutions, including air, hydraulic, and servo-powered rams. From basic manual systems to fully automated roll marking machines designed for high-volume industrial applications, CMT provides reliable, high-quality marking solutions tailored to your production needs.

Air Powered Roll Marking: A Turnkey Solution for Precision Marking

Columbia Marking Tools' classic roll marking machine is designed for high-performance, high-volume marking applications, featuring a custom-engineered ram cylinder that delivers the precise force needed for consistent marking pressure.

This innovative roll marking system combines durability, precision, and adaptability, making it an excellent solution for manufacturers seeking efficient, repeatable, and high-quality marking results.

Hydraulic Powered Roll Marking: A Cost-Effective Solution for Precision Marking

Columbia Marking Tools' 410 Hydraulic Roll Marking Machine is built for power, precision, and efficiency, featuring a custom-designed ram cylinder that delivers exceptional marking pressure. This advanced system enables the deepest and fastest part marking available, making it ideal for heavy-duty industrial applications.

The 410 Hydraulic Roll Marking Machine is the ultimate solution for manufacturers requiring high-performance, deep marking capabilities in a robust and adaptable system.

Barstock Marking Machines: Revolutionizing Manufacturing Marking

Bar stock marking is a specialized form of roll marking, where a round die continuously presses against a moving hexagonal or round metal bar, imprinting essential identifiers such as fitting sizes, manufacturer names, or logos. Traditionally, bars ranging from 3 to 20 feet (0.91 to 6.1m) long are manually fed into the machine, where power-driven marking dies automatically process them.

Columbia Marking Tools is the leader in this specialized machinery, and continues to advance this technolgy to meet today’s demanding production requirements.

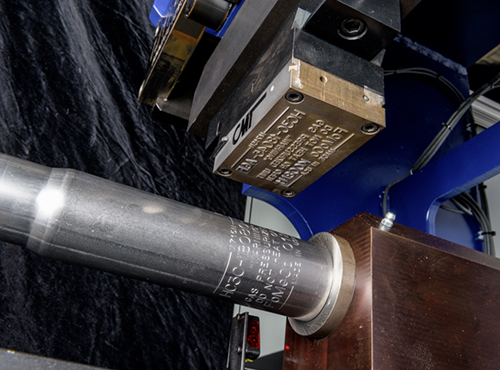

Diameter 2 Diameter Roll Marking Machines: A Space-Saving Solution for Round Part Marking

Diameter-to-diameter marking is a specialized technique developed by Columbia Marking Tools (CMT) for efficiently marking the circumference of round parts. This unique marking method is designed to reduce floor space requirements and minimize force, making it ideal for applications that involve long marking legends on cylindrical components.

By optimizing the marking process, CMT’s diameter-to-diameter marking system provides a precise, high-quality mark while ensuring greater efficiency and durability in production environments.