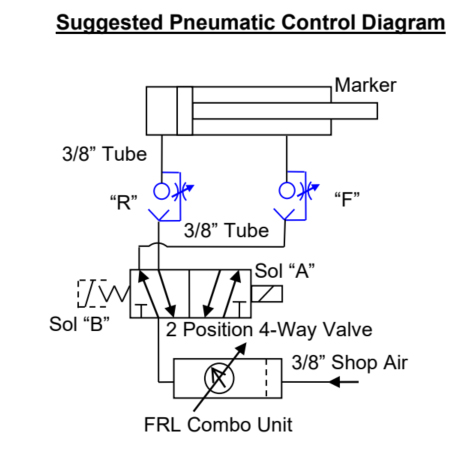

Hot Stamping Air Preparation

The importance of good compressed air supply.

Hot Stamping requires a larger and more instantaneous air flow compared to standard air cylinders because they need to deliver a high force in a very short period. This rapid burst of air creates the impact necessary for marking applications, especially in industrial environments where precision and speed are critical. Unlike typical air cylinders, which operate more gradually and can sustain a consistent flow over time, air impact markers must compress and release air quickly to achieve the desired marking force, making fficient air flow management crucial for their performance.

Two Most Common mistakes when preparing an air circuit for hot stamping:

- Air Starvation

- Cycle time too long